4mul8 Machinery Auto Rotary Milking Parlor 60 Cows Puller + Flow Meter

Our very own 60 Cow Rotary Milking Parlor with Automatic Cup Puller + Milk Flow Meter. Quality milking parlors are absolutely essential for large dairy farms and milk-producing operations. We offer included upgrades, installation and much more. This particular model features a round platform, an automatic pull-off, meaning that you no longer need to stand there while milking.

This mechanism will automatically pull out the cluster, releasing it from the cow's teat. The Automatic milk flow meter is an added bonus. We have had no issues with our machinery so far! Rest assured, you are in good hands! The most commercially utilized parlor installation to date is this type of milking parlor, for large producers.We offer a more economical, less-automated version as well, be sure to check it out! Standard concrete countertops have been used in the ranch industry.

For more than 20 years, the design has been recognized as an industry leader by the turntable standards and has long proven to be the right choice for pastures in the US, New Zealand, Europe and many countries. This milking parlor features a robust structure and engineering-integrated design. The machine system is perfectly matched, and the convenient. Assembly design greatly improves the installation speed and. The 2.7 m wide countertop provides.

Good protection for the milking equipment and electronics below. The design of the turntable provides the operator with a clean, smooth operating system. With fast milking conditions, the flow of cattle on the upper and lower turns is very smooth and the milking equipment is at your fingertips. The direction of rotation of the turntable can be.

Operator consoles, safety and protection devices are supplied with the turntable. Purchasing a 4mul8 Machinery® Turntable is a truly proven technology investment. The advanced design ensures that there are no additions and modifications to the site during installation. Any increase in equipment may seriously affect the compatibility of the turntable. This is worth reminding everyone.60-position heavy-duty turntable system, with modular design and fully sealed bottom plate. Main components of the chassis are made of 304 stainless steel and hot-dip galvanized steel, high-strength. Fiber concrete countertops, heavy-duty dual-track structure and carbon fiber composite rollers, 6 + 2 drive. A full range of safety protection devices can meet the 24/7 non-stop safe and stable operation requirement. The materials used by the milking equipment in contact with the milk milking cups, milk tubes.

Washing water pipes and seals, etc. Comply with the relevant national food container and packaging material. The vacuum part adopts an efficient and quiet maintenance-free oil-free vacuum pump set, which is. Matched with a step-less inverter, which is environmentally friendly and energy-saving.

Precise electronic metering and automatic cup removal and milking position. Used is the control and human-computer interaction device of the system. Milk conductivity can monitor cow mastitis early, and accurate and consistent milking parameters can. In order to achieve a full range of ranch management, the 4mul8 Machinery.Management software used by the milking parlor data processing can continuously monitor the production. And health and reproduction status of dairy cows.

All information is collected and reports are automatically. 60-position turntable rack - I. The main components of the chassis are made of 304 stainless steel and hot-dip galvanized steel, the table top is made of high-strength. Fiber concrete, and a 24MM thick rubber pad is laid on the cow stand.The five-sided special-shaped box body is tilted forward 10 ° at the same time and bent with an arc cutter, which greatly increases the manufacturing difficulty. However, this also adds more room for entering the bull and easier operation for the 13 ° italic. At the speed of 7min / r, increase the feeding time (theoretical value) of at. The control panel is parallel to the outer edge of the turntable, which. Also makes the operation more convenient.

The arc cutter is used to bend so that the. Car body has no sharp corners as a whole to protect the cattle to the utmost. 13 degree italic cow position.

The cow position is inclined at 13 degrees relative to the center of the turntable. This design facilitates the entry and exit of cattle, improves the efficiency of the. Turntable, and effectively prevents pinch cattle. All parts above the plate are made of 304 stainless steel, which is beautiful and durable.

60-position turntable rack - II. Spliced fully enclosed heavy chassis. The idea of splicing fully enclosed chassis is to increase the.

Convenience of on-site installation and water resistance in use. Chassis is assembled with building block type screw splicing at the. Installation site without the need for electric welding. Problems such as chassis leakage will occur during the use of the. Carbon fiber has extraordinary abrasion resistance, fatigue resistance.

However, because of the high cost and difficulty of. Processing, few companies in the animal husbandry industry use such. Our affiliated metal-works company customizes industrial-grade pressure-resistant materials. CFXX for turntable products, and processes them using CNC alloy molding.

Designed to find new solutions for pressure. Rollers for the livestock industry. Heavy load on upper and lower double rails.The upper and lower double track intermediate roller structure is the standard structure of the heavy turntable. Its guidance, stability and durability all surpass the single track structure.

60-position turntable rack - III. Drive motor imported from Siemens. The drive module is externally mounted, and the rotary disk is driven by an external friction transmission method. It makes it possible to maintain the power system without stopping, and enables the turntable system to realize 7x24 non-stop operation. The fully enclosed structure of the overall drive system makes operation safer. Newly designed service arm with adjustable milk tube support to reduce cup leak. The self-made stainless steel waterproof button is set on the side of the box. The ergonomic design makes the operation of the milker easier. The detachable roller changing mechanism is an original design. A section of the lower track is equipped with a quick release device.If the roller needs to be replaced, the quick release track only needs to be removed, and the roller can be removed and replaced. 304 stainless steel skirt, beautiful shape to prevent sewage and dirt from entering the turntable track to reduce noise disturbing cattle. The original imported center rotary kettle can transmit power. Communication, vacuum and milk for the turntable.

The whole parlor is stainless steel, all power and communication brushes are connected with double brushes to facilitate uninterrupted power and communication. 160 mm vacuum connection 76 mm milk connection. Completely separated electric slides with 15 electric slides.

30 amp brushes (two per slide) external electrical connection box. Unique adjustable support can ensure the accuracy of installation. Reduce the fear of cattle due to height differences.Reduce the stress response of cows during milking and equipment maintenance. Reduce the saliva of cattle from dripping from the inner ring of the turntable. The Rod-less magnetic track positive pressure cup removing cylinder is a precision industrial product without wearing parts and the extension rod is more durable than traditional cylinders. Driven by compressed air without affecting system vacuum. 304 stainless steel case with rounded corners.

The upper part is an embedded touch-screen. Tablet computer that supports HDMI video. The outer ring adopts the German.

Bernstein brand, and the inner. Circle adopts the Pizzato brand. Imported heavy wire switch, and.The waterproof grade IP67 is. Structure is connected to the inlet. And outlet door of the cow, both. Of which are started at the same. Uses the F&P brand in France, and.

Connection of the cleaning pipeline. The Pizzato brand from Italy, a. Used to secure the front of the. Milk tank, preventing damage to.Using the German KOMAX brand. It is fixed under the rail, and the. Emergency stop program can be.

Started quickly if the rail or roller. The French F&P brand is used to. Monitor the temperature of the. Inner and outer ring of the rotary. The turntable stops when the. Small and exquisite, it can provide very stable pulsation frequency and pulsation ratio. The pulsation number can be set from 31 steps, from 50. Times / minute to 80 times / minute. The pulsation ratio has 8 stages before and after. The world's most advanced waterproof electronic pulsator can clean the internal system of the pulsator through a pulsation tube, and can work. It has exactly the same pulsation frequency, so the milking frequency of each. Cow is exactly the same.The completely sealed waterproof electromagnetic coil is extremely waterproof. And can be immersed in water without affecting its function. Easy to install and disassemble, less wearing parts and low maintenance cost. The entire pulsator contains only 8 accessories and no tools are required for.

The pulsator uses special wiring, which has the functions of waterproof and. Kishihiro triangle milk lined milk. Reduces air volume and opens and. Closes the milk liner more. The milk liner rarely moves, softening the opening.

Lighter cup group reduces nipple stress. More uniform movements to reduce keratinization. Easy to clean Strong and. Rugged but light weight, PPSU food-grade. High-strength material, sturdy and durable. Resistant to stepping and falling. Milk inlet and outlet improves the vacuum.Stability of the nipple end during milking. Kishihiro ImpulseClaw 350 Milk collector.

The impeller is machined from cast iron and is permanently fixed. Vertical installation, durable, all structures adopt welding. The impeller is designed with the principle of dynamic balance. Which will not cause vibration during operation.Extremely high pump installation position for easy maintenance. The inner surface of the cast iron plate is polished and is very fine. Smooth bearing seat can ensure accurate position. Open structure can quickly cool down. The speed regulating gear is made of alloy, which is durable.

Governing gear and gear ring are lubricated by lubricating oil. The innovative InterPuls iDrive100 variable speed governor is a special model developed for vacuum systems, reducing.

Consumption, noise and maintenance costs, and ensuring maximum stability of the vacuum during milking. Works with reliable sensors to ensure faster response times and improve vacuum stability.

Designed for ranches, the motor speed can be adjusted automatically according to the vacuum of the system, which can. Reduce energy consumption by about 50 compared with a motor system running at a constant speed. Working range -100 ÷ 0 kPa. Power supply 24VDC ± 3V. Overload protection, external light alarm. High-precision vacuum pressure sensor, which can display the vacuum. Pressure value of the system in real time. CTA GPV5000 Oil-free Vacuum Pump Unit. 50KPA maximum extraction volume can reach 6000 liters / minute. Equipped with 11KW Siemens motor, silencer system and all PVC. Compared with the water ring pump and the oil vacuum pump, the. Pump has two 8-shaped impellers in opposite directions, which.Requires no refueling, so the running cost is low. Longer service life and lower maintenance costs. Low noise, no pollution to pasture environment.

The pop-up vacuum safety valve is compact and easy to install, ensuring the integrity. Of the milking system and the health of the cattle. If a sudden increase in vacuum. Occurs, the vacuum safety valve will deflate in time to protect the cow's. Udder, and the device will issue a sharp whistle to remind the operator to check the.

InterPlus STABILVAC 6000 Vacuum Regulator. Equipped with 2 sets of vacuum regulators to meet the pressure regulation capacity of 0-12000L.The Stabilvac 6000 vacuum regulator is equipped with a precision sensor (SPV), which can. Continuously detect the vacuum value and compare it with a preset value. Valve (MCV) allows the appropriate airflow to enter, thereby suppressing Constant and precise. Vacuum during the milking process.

Made of stainless steel, milk is filtered through a milk filter equipped with. Filter paper, which can filter out impurities in the milk and improve the. A double stainless steel filter is installed, and the filter paper can be.

Replaced during the milking process without affecting the milking. Milk receiving system mainly includes milk receiving tank, milk tube, milk. Pump, pneumatic butterfly valve and check valve, air milk driving device. Liquid level controller, automatic control switch, milk water separator and. 2 sets of 100L milk receiving tanks are 304 stainless steel. Double-circulation milk tube adopts food-grade stainless steel tube with elbow. And connection parts made of stainless steel.2 sets of 2.2kw stainless steel milk pump and milk pump check valve. 2 sets of 37L milk separator, when milk and water enter, automatically cut off the. Vacuum to protect the vacuum pump. Each time the milking machine is cleaned, the. Milk-water separator is automatically cleaned to ensure the hygienic quality of the.

After cleaning, the water in the pipeline will be automatically discharged. Through the drain valve to prevent the water from mixing into the milk. Stainless steel air milking valve, after milking, can clean up the remaining.Milk in the milk pipe, no cows. Electronic metering system - I.

®'s choice of pressure. Gauges have been certified by ICAR International before they go on the market. The measurement error is within ±. 1.5, making it one of the most accurate measuring equipment on the market.

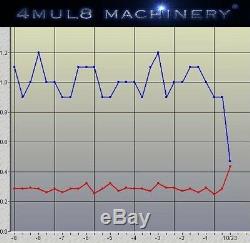

The MPC meter can monitor the milk's electrical conductivity online in real time, detect and analyze the electrical conductivity of each cow to detect breast health, and expose mastitis. The legend is that the electronic meter automatically monitors the milk conductivity change of each shift, and the ranch management software calculates the deviation in real time to expose mastitis. Electronic metering system - II. The drawing in the picture is a typical cleaning cycle diagram, followed by the pre-flushing phase. (a) When the water temperature rises to the thermal cleaning setpoint (d), enter the thermal cycle cleaning stage (b). Water temperature drops below the set-point (d), it enters the post-washing stage. When the cycle cleaning starts, a conductivity line. When an abnormal condition is detected during the cleaning process, the cleaning fault alarm can be queried in the. The built-in temperature sensor of the MPC meter can monitor the temperature of the cleaning water in real time during the cleaning process, and the. Conductivity monitoring can track the concentration of acid and alkali in real time. Insufficient cleaning water Pre-wash water temperature is too high.Milking process control (1 set of cups, 2 sets of cups, returning residual milk, back flushing). Pulse control (pulsation frequency, pulsation ratio, flow rate control pulsation, pre-pulsation). Stimulating massage (massage intensity, massage time, automatically stop feeding). Automatic cup removal the flow rate of cup removal can be adjusted in the range of 120 3000ml / min, the time.

Delay of cup removal, quick cup removal, kick cup. Compulsory milking lock special cows such as unidentified cows / dry cows / anti-milk cows are prohibited from. Milking through advanced code settings. Cream milk is automatically removed from the cup (the milk milk is stopped during milking).Customized milking schemes for different characteristics of cattle (16 control parameters, 100 code combinations). Control panel is an integrated controller that can. Independently display and set milking parameters, monitor the milking. Operation process, and achieve precise / assisted / smart milking. Control and display device of MPC panel system.

At the same time, the control. In addition to the usual milking and cup removal functions, the. Milker can also send information to the computer through the panel to report the. Situation of a cow to the management system, and managers can easily query this. Least abnormal injuries Bionic milking.

Avoid excessive milking Accurate and. Minimal milking time Consistent pre-lactation. Milk production and milking control. Automatic cup removal and cup drop alarm Mastitis monitoring and alerting. Cup group automatically lift / fall.

Automatic control of turntable resistance door (manual milking, kick cup, high conductivity, code). The MPC control panel can alert the abnormal status of the current cattle, view the status data of the current cattle. Through different combination instructions, and add and delete codes to the current cattle as required. The milk management software, hand-picked by 4mul8 Machinery. Is the most advanced and comprehensive herd management software, with the following characteristics.

Accurately measure the milk flow rate to achieve accurate automatic cup removal. The milking operation of the milker can be monitored to detect violations in time, and the milking curve can be automatically generated to. Evaluate the milking operation procedure.

It can monitor pedometer, meter, cleaning, milking efficiency and other abnormal conditions. Record the milking situation of each shift of the cattle, monitor the mixed herd situation, and summarize the output of each shift, day, month. Collect and store data - Automatically generate reports. A Automatically record various data of each cow milk production per shift, milk production efficiency. Electrical conductivity, milking time, activity, DHI data, sitting data, etc.

Automatically generates various statistical reports, such as calving and survival rate, calving. Report, calving report, weaning report, herd movement, herd structure, elimination report, diagnosis.

Summary, disease report, breeding Reports, breeding summary and more than 100 reports. Detailed health monitoring to single-headed cattle. By monitoring the changes in milk production and milk production efficiency of each cow, the Afigen system reminds you at any time which cows' milk production has decreased, so that the veterinarian can check the health status of these cows in time, treat them early in the disease, and monitor the veterinary work , Efficacy monitoring.

Knows the health status of cows' breasts at any time by detecting changes in the milk's electrical conductivity. Occurs, it will show an increase in electrical conductivity. At this time, the system will list these cattle so that mastitis can be detected early in.S pedometer monitors the changes in the activity of dairy cows, and finds cows with limb and hoof problems early. Veterinary treatment list, prenatal care, postnatal care list as needed, and promote veterinary treatment prevention efforts.

Automatic monitoring of estrus and analysis of breeding work. Each cow wears a pedometer, which can realize 97% automatic estrus monitoring. As well as leak detection, abortion monitoring, and error detection.

Need to be inspected, reminded to re-examine cattle, statistics and forecast of. The pedometer can also monitor reproductive diseases, such as ovarian cysts and apathy, and the same period program. Summary of breeding reports, monitoring of overall breeding levels, cattle estrus interval, breeding interval, calving interval, each stage.Calculation of mating pregnancy rate at different times, breeding, pregnancy statistics. Best tools for large ranches. Fewer data views, manual operations. More meaningful data, automated processes.

Less waiting, finding, losing, time, and more automation, control, authority, data. Smarter Automatic filtering for fertilized cattle saves more labor.

Automatic filtering options: group adjustment, pre-check, hoof repair to avoid false. Alarms (especially for large groups). Find sick cows using rest time, activity, and number of lying down. Using artificial intelligence algorithms to analyze changes in group behavior over time.

Congestion alert for each group of welfare index. Group adjustment warning (too many group adjustments will lead to less rest) Overall group. Calving is about to begin. Time to transfer the cattle to the transfer room. If calving continues for too long, we will let you know that It takes too long to calve!

Check if the cows are in time. Stainless steel cleaning base: foldable design, folded to the side of. The table when milking, does not take up space; prevents vacuum. Air impactor (surge device), which. Automatically injects air intermittently during. The cleaning process to form a water column. To enhance the cleaning effect. The automatic cleaning system includes an automatic cleaning control panel, a cleaning agent.Injection pump, an air impactor, a milk cup cleaning seat, and a stainless steel cleaning sink. The cleaning effect is good. Simple operation and labor saving.

Can provide 5 kinds of cleaning programs, each program has 7 kinds of cleaning options. Prepared for each and every week cleaning different cleaning programs.

Cleaning, the water in the pipeline can be dried to ensure the cleaning quality, reduce the. Consumption of cleaning agents, and improve the quality of milk.

The cleaning time can be. At the same time, the system can also be started manually to.

Perform automatic cleaning and stop automatically. There are two cleaning agent extraction pumps, which can automatically extract different. Cleaning agents and pipe disinfectants in different cleaning stages. The herd weighing system can be. Automatically identified after the cows are.

Milked and passed through the herd weighing. The cows that need to be processed. Disturbances in daily behavior improves cow. The time spent searching for cattle accounts for more than 50% of.

The group weighing system greatly reduces the workload of ranch employees and. Taking breeders as an example: The breeding workload of 3,000 ranches. Breeding: about 24 heads per day. Pregnancy test: about 24 heads per day. Injection: about 30 heads per day.

There are about 78 heads of breeding and processing cattle per day. Processing time of each cow is three minutes, 78 3 minutes = 234 minutes 4. Hours, and one breeder can handle it! Keep track of the cows that need treatment. When the cattle pass through the herding gate, normal cows return to the shed, and the cows to be processed are automatically separated by the herding gate.After the normal cows of the group return to the original shed, the separated pending processing is performed. The cattle rushed back to the original shed and. Separated it from other normal cattle with a temporary partition door. After the breeder / vet has finished processing, the temporary partition door is opened, and.

The cattle can return to the original herd freely. Not only improves staff efficiency, but also minimizes stress disturbance to the herd. When the cattle pass through the herding gate, the weighing platform recognizes the cattle weight data and sends the data to the.

Management software automatically saves the weight data to the cattle database by. Functions of the weighing system. Discover the energy balance of cattle. Transfer postpartum cattle to low-energy diet herds in a timely manner. By monitoring the change in body weight, timely detection of sick cattle.

When the energy is in balance, find the best insemination period. Changes in dry milk weight indicate problems with dry cow breeding.

The speed of milking is controlled by the automatic milking control system to automatically control the speed of the. Cow drive, so that the cows can enter the milking table quietly and smoothly. Large span cow catcher, the maximum distance is 12 meters. Compressed air-driven heavy-duty bull-catcher, which is specially designed for 24-hour work.

The frame beam is 150 x 75 MM hot-dip galvanized square steel and 200MM round steel. Drive shaft is 1.25 x 12', CD1018 steel rod. Before installing the bull-driving device, the ranch needs to be equipped with the track of the bull-driving. Device, and a 2.1-meter-long post is installed every 1.2 meters. (600MM buried underground), two horizontal rails in the middle, and the track uses 10-gauge steel.

Cow identification and estrus monitoring system. The collar is a high-low dual-frequency design.

It has both a milk parlor identification (200KHz low-frequency short-distance transmission) and a cowshed identification (868MHz high-frequency long-distance transmission). It can monitor real-time activity amount, number of lying times, lying time and other data. The data collection frequency can be adjusted from 5 minutes / time to 60 minutes / time.

The battery has a life of up to five years and automatically enters airplane mode when no receiver signal is received for two hours, saving power. The maximum identification radius of the data receiver can reach more than 300 meters.

Housing, AC / DC input voltage. When using DC power supply, it can be installed outdoors in any place with network. Turntable recognition system is an entry-type "in-place" recognition system that can effectively avoid misalignment recognition. The recognition rate is over 99% and the recognition accuracy rate is 100%. Identification after entering the milking position. Recognizes location and precise adjustment of recognition distance. The recognition rate is over 99%, and the recognition accuracy rate is 100%.The second-generation estrus monitoring system is the best comprehensive solution. S hand-picked accurate identification system, it uses integrated algorithms to monitor yield analysis, activity.

· Breeding increases the rate of estrus exposure by automatically revealing estrus, which in turn increases. · Health through early exposure + early treatment to achieve high milk yield and high reproduction rate. · Comfort level Monitors disease through the collection of individual rest time, and monitors comfort level.

Through the collection of group rest time, and then monitors bedridden problems, heat stress and density. The second-generation estrus monitoring system reports calving early warning by monitoring the number of. Prenatal births and sends the early warning information to the staff mobile APP in a timely manner. Cow Identification and Estrus Monitoring System. Find the cattle that need insemination in.

The fastest, easiest and most accurate way Real-time view of rest time, activity level. And number of lying on the ground. Real-time monitoring of cow rest. According to the change of lying and standing. Time and the change of activity amount.

Predict the rest of the cows. Report in real time, find out the problems in.Time, and let the cattle get more rest. 1 hour of rest = 1.7 kg of milk. Reduce and Eliminate hormone use.

Each unit adopts a microcomputer logic control system developed by the Atlas Group. It has self-diagnosis and self-protection functions. The display panel can show the actual operation of the unit, and it can realize the system self-check before startup.

Monitor all safety-related parameters during operation. If the unit fails, the computer control system will respond accordingly according to different situations. Can work safely for you 24 hours a day, unattended. The unique microcomputer logic control system designed and developed by the Atlas Group is the most advanced control system in the industry. Its microprocessor can monitor the pressure change of the system at any time to make the most effective adjustment to meet the system's gas volume requirements.2.1m3 / min Working. BLT-15A Displacement: 1.65m3 / min Exhaust pressure: 8bar Maximum power.

11kw Cooling method: Air-cooled Transmission method: Belt host: Atlas SAP. Total running time / loading running time. Exhaust temperature of main engine is too high Control power failure.

Exhaust pressure is too high. Reverse motor APRS reverse phase. Compressed air system configuration diagram reflected in pictures.

Third year, 80% in the fourth year. 20% in the fifth year. After sales service for life. After the equipment is in operation, the service engineer will prepare a service plan for the customer in advance and go to the site to carry out maintenance and maintenance of the equipment system to prevent failure in advance. Response service: 24-hour telephone and network response, response time 2 hours, and processing within 24 hours.After-sales service: Once every 2 months (6 times a year) on-site system (software and hardware) overhaul, pasture production technology. After each service, issue service reports and suggestions, such as: overall equipment operation, consumable parts.

Milking hall hygiene and management recommendations emergency drills, production management recommendations. Installation and training period: 40-45 days. If a goat milking parlor is needed, please specify while purchasing. Yes, every item mentioned is already included and this is all that you need to start milking your cows or goats. We can offer grinders and mills as well, just ask! Investment return recommendation: According to our previous experience, the complete system of cattle of different scales will recover the. Investment cost in the case of correct use for 10 to 20 months. 30 years of scientific cattle breeding experience and mature and effective production. These units help the pasture to achieve long-term maximum profitability of the system engineering. As always, Excellent Customer service available around the clock to serve you. UK and most of Europe - 22-27%. Normally it is 5% or 10% of our cost, not yours. You can be assured that your order is in good hands, and will feel satisfaction in knowing that you have ordered top-quality machinery from a transparent supplier, who puts customers first. We have already thought of the upgrades before you ask for them.We offer all the bells and whistles at an affordable price, to keep it simple. Now I ask you, why 4mul8 Machinery ®? All factory defects are taken care of by us! The item "4mul8 Machinery Auto Rotary Milking Parlor 60 Cows Puller + Flow Meter" is in sale since Tuesday, January 14, 2020. This item is in the category "Business & Industrial\Agriculture & Forestry\Livestock Supplies\Dairy Cattle".

The seller is "qualitycounts403" and is located in Calgary, Alberta. This item can be shipped worldwide.

- Model: RMP-60 AS (Auto - Signature Model)

- Country/Region of Manufacture: China

- Custom Bundle: Yes

- Material: Stainless Steel

- Power Source: Electric

- Type: Milking Machine

- Brand: 4mul8 Machinery®

- Bundle Description: Automatic Puller

Automatic Milk flow meter

Intelligent milking system

Delivery

Installation

Warranty

Duties paid for USA and any country with a 0% duty on agricultural and dairy machinery.